|

> Home

> About Ultrasonics

--------------

> Cleaner Types

> Transducers

> Tank Types

> Vapor Degreasing

> Our Experience

> New + Custom

> Rebuilt Equipment

> Repair Services

> Cavitation Meter

> Used + Rebuilt Equipment Inventory

--------------

> Industrial Ultrasonic Cleaners

> Ultrasonic Cleaning Consoles

> Cleaning Lines

> Solvent Equipment

> Other Ultrasonic Cleaning Equip

> Contact us

|

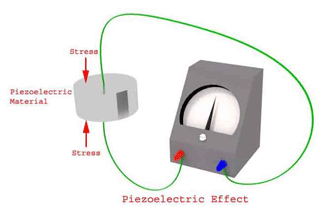

The transducer converts high frequency electric energy to mechanical energy that produces cavitation in the cleaning media.

Piezoelectric or Electrostrictive

This type of transducer is the most common. Most are currently made using lead zirconate titanate ceramic crystals. They are bolted between an aluminum driver cone, and a back plate. They are resonant devices, and the resonant frequency is determined by the dimensions of the driver cone and back plate and the crystal dimensions. The can be designed to be resonate at a broad range of frequencies, from 25 kHz to about 180 kHz. The piezo crystal changes in dimension when expected by an electric signal, causing cavitation in the liquid in the tank.

Types of Piezoelectric

|

|

Block

This is the oldest type, which is a solid block of barium titanate bonded to the tank bottom. This was 1950's technology. The last time we saw these being manufactured was in the 1990s. |

|

|

Wafer or Pancake

Lead zirconate crystal bonded to an aluminum disc, with the aluminum disc bonded to the tank bottom. These are used on most of the benchtop units. They are low powered, and subject to more failures than the industrial Langevin transducers. These lower priced transducers work well, and their lower cost has put many small, affordable bench top cleaners on the market.

|

|

|

Langevin or Sandwich Transducers

These are usually lead zirconate titanate crystals, bolted between an aluminum driver cone, and steel or aluminum back plate. They are used on all of the state of the art piezo industrial ultrasonic tanks. They are repairable in most cases, since crystals on most brands are replaceable.

|

|

|

Push Pull, or Rod Transducers

Push pull transducers are stainless steel rods that bolt into the cleaning tank. These are powered by piezoelectric crystals mounted on one end of the rod. These are a European development, and work well in large tank installations. They are not as popular in the USA as the styles of transducers previously listed. We do, however we also sell and service these.

|

|

|

Magnetostrictive

More expensive than piezoelectric, but are capable of producing higher power levels in the cleaning solution. The transducer consists of nickel laminations fastened to the radiating surface of the tank or transducer. The nickel laminations are ferro-magnetic metals that exhibit dimensional changes when excited by a high frequency varying magnetic field. The magnetic field is produced by an ultrasonic generator. The transducer changes electrical energy to mechanical energy in the cleaning solution. This type of system is usually limited to the lower frequency ultrasonic range from 18 kHz - 25 kHz.

|

Alexy Ultrasonics Corp.

86 Jim Stephenson Rd.

Swan Lake, NY 12783

Phone: |

|

(845) 482-3000 |

FAX: |

|

(845) 482-3040 |

This site is ©2003 - 2020 Alexy Ultrasonic Cleaners.

|

Please report broken links and other web problems. Thank you!

Website by Tech Lab 2020

|

|